EDGE ROUNDED LASER CUT SCREENS

sales@dsd.com.au

No Sharp Edges on DSD Products

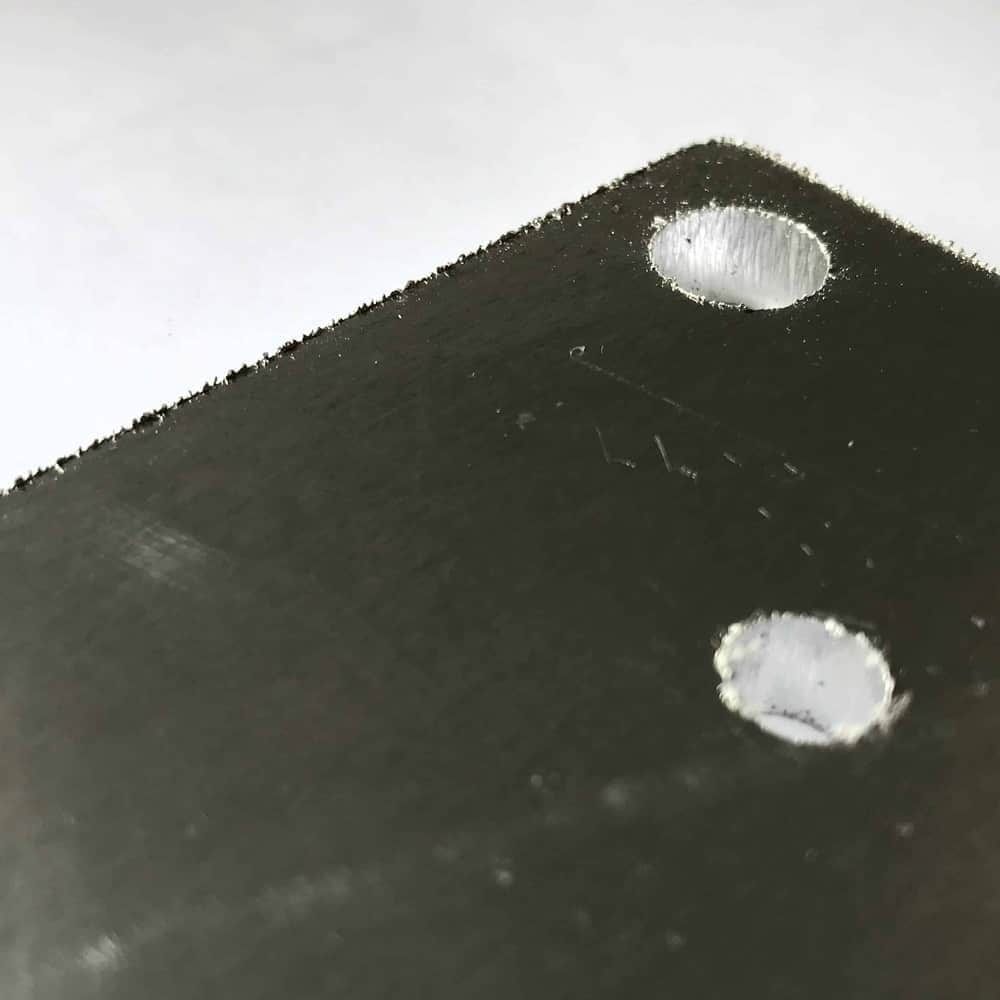

All our aluminium Decorative Screens are Edge Rounded. This process ensures a complete finish to your screens. In almost all cases there will be a fine sharp burr that is left after the laser cutting process is

complete. If this burr isn’t removed there are several potential problems you could face. The benefits of edge rounding to aluminum include:

· Improved safety: Edge rounding reduces the risk of injury from sharp edges, making the material safer to handle and work with.

· Enhanced aesthetics: Edge rounding can give aluminum a smoother, more finished appearance, which can be particularly important for products with visible edges.

· Increased durability: Rounding the edges of aluminum can help prevent powder coating from chipping and cracking, which can increase the lifespan of the material.

· Improved corrosion resistance: Sharp edges can create stress points that are more susceptible to corrosion. Edge rounding can help distribute stress more evenly, reducing the likelihood of corrosion.

Unfortunately, this process is not used by the majority of screen suppliers. The combination of this and

all our production processes means you will have a decorative screen that will look excellent for many years to come.

The DSD Production Process

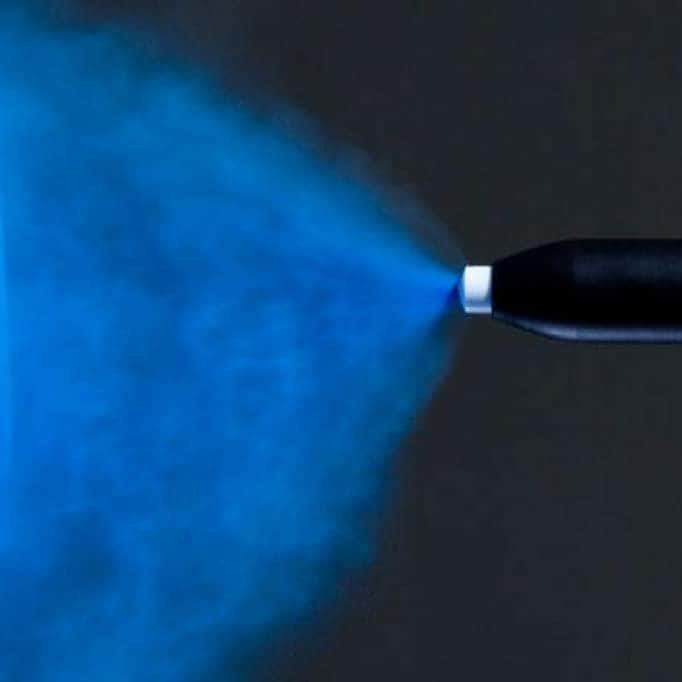

Laser cut precision

All screens are optimally cut in house on our state of the art German Trumpf Laser Cutting Machines, all programmed using the latest CNC CAD software.

Edge Rounding

All our screens and products are passed through a linishing machined which removes swarf and rounds all the edges. This process is pivitol for better powder-coat adhesion plus the added safety of no sharp edges.

CNC Folded

We precisely fold our screens and products using our in state of the art CNC Brake Press. All edges are folded with pin point accuracy ensuring we supply your screens to your exact measurements.

Powder Coating

Our screens are only powder-coated by trained & experienced technicians. This means you get a product that will look great for years to come. Plus we have a large range of colours to suit any colour palette.